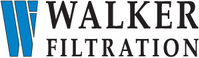

Compressed Air Coalescing Filters

Compressed Air Coalescing Filters

Models | A30006 to A31500

Flow Rates 6SCFM (10Nm3/hr) to 1500 SCFM(2550 Nm3/hr)

Introducing Alpha, Walker Filtration’s latest range of market leading compressed air and gas filters. With enhanced housing features and a step change in element performance, Alpha Filters deliver a high quality filtration solution you can trust.

Offered in a range of 19 models with connection sizes ranging from 1/8″ to 3″, the Alpha Series has been tested to provide a saturated differential pressure of <1.8 psi. (125 mbar) across X1 and XA grades – proving to be our most advanced filter to date.

With class leading performance and exceptional results in oil aerosol and particle retention, Alpha delivers significantly reduced pressure loss and optimum filtration efficiencies – to ensure continually low operational costs.

|

|

|

|

NEW Modular Filter

Low cost connecting kits and new filter head design enables easy close coupling assembly |

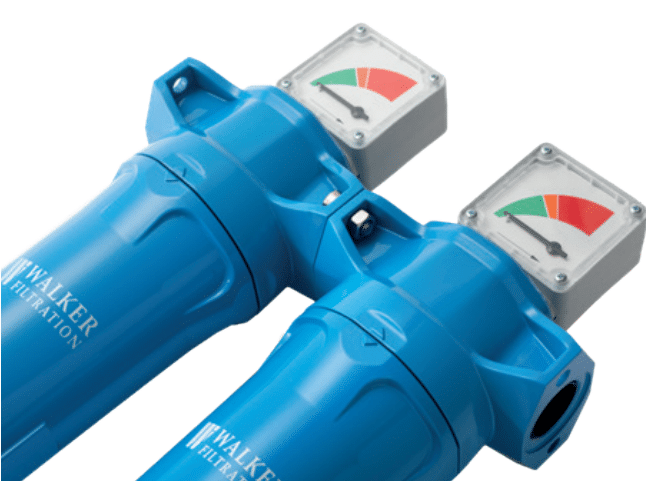

NEW Filtration Technology

Alpha deep pleated media technology delivers a step change in performance |

NEW Externally Accessible Drain

Eliminates the need to access the inside of the filter housing when servicing the drain |

-

Flow-Optimized Design

Advanced filter head design for optimized flow performance

-

Flexible Installation

Modular design and accessible fixings enable simple close coupling assembly

-

Market Leading Performance

Custom engineered filtration media delivers optimum performance in line with air quality standard ISO 8573-1: 2010

-

Simplified Serviceability

New externally accessible drain, profiled bowl design and unique push fit elements ensure quick and reliable maintenance

-

Corrosion Protection

Internal and external electrophoretic paint finish followed by a tough exterior polyester powder coating

-

Color Coded Element End Caps

Easy and accurate grade identification

-

Product Safety in Mind

Guaranteed safe housing closure with rotational safety stop

Technical Specification

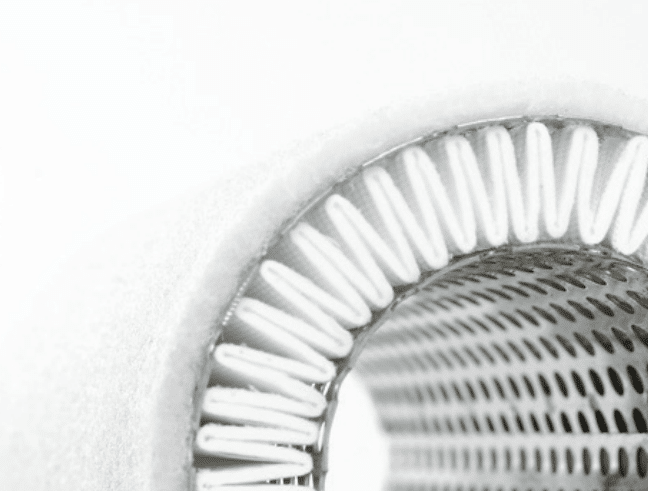

| Filter Model | Pipe Size Inches | Inlet Flow Rate* | Dimensions Inches (mm) | Weight | Element Model | |||||

| SCFM | NM3/hr | A | B | C | D | lbs | kg | |||

| A30006 (grade) | 1/8 | 6 | 10 | 1.97 (50) | 0.67 (17) | 6.18 (157) | 2.36 (60) | 0.6 | 0.3 | E30306 (grade) |

| A30015 (grade) | 1/4 | 15 | 25 | 1.97 (50) | 0.67 (17) | 6.18 (157) | 2.36 (60) | 0.6 | 0.3 | E30306 (grade) |

| A30025 (grade) | 1/4 | 25 | 42 | 2.76 (70) | 0.91 (23) | 7.44 (189) | 2.76 (70) | 1.3 | 0.6 | E30408 (grade) |

| A30032 (grade) | 3/8 | 32 | 54 | 2.76 (70) | 0.91 (23) | 7.44 (189) | 2.76 (70) | 1.3 | 0.6 | E30408 (grade) |

| A30050 (grade) | 1/2 | 50 | 85 | 2.76 (70) | 0.91 (23) | 9.09 (231) | 2.76 (70) | 1.3 | 0.6 | E30412 (grade) |

| A30070 (grade) | 1/2 | 70 | 119 | 5.00 (127) | 1.26 (32) | 11.22 (285) | 3.15 (80) | 3.7 | 1.7 | E30612 (grade) |

| A30085 (grade) | 3/4 | 85 | 144 | 5.00 (127) | 1.26 (32) | 11.22 (285) | 3.15 (80) | 3.7 | 1.7 | E30612 (grade) |

| A30105 (grade) | 1 | 105 | 178 | 5.00 (127) | 1.26 (32) | 11.22 (285) | 3.15 (80) | 3.7 | 1.7 | E30612 (grade) |

| A30125 (grade) | 3/4 | 125 | 212 | 5.00 (127) | 1.26 (32) | 14.57 (370) | 3.15 (80) | 4.4 | 2.0 | E30621 (grade) |

| A30175 (grade) | 1 | 175 | 297 | 5.00 (127) | 1.26 (32) | 14.57 (370) | 3.15 (80) | 4.4 | 2.0 | E30621 (grade) |

| A30280 (grade) | 1 1/4 | 280 | 476 | 5.51 (140) | 1.61 (41) | 18.74 (476) | 3.35 (85) | 10.8 | 4.9 | E30731 (grade) |

| A30320 (grade) | 1 1/2 | 320 | 544 | 5.51 (140) | 1.61 (41) | 18.74 (474) | 3.35 (85) | 10.8 | 4.9 | E30731 (grade) |

| A30400 (grade) | 1 1/2 | 400 | 680 | 6.69 (170) | 2.08 (53) | 20.00 (508) | 3.94 (100) | 10.8 | 4.9 | E30831 (grade) |

| A30450 (grade) | 2 | 450 | 765 | 6.69 (170) | 2.08 (53) | 20.00 (508) | 3.94 (100) | 10.8 | 4.9 | E30831 (grade) |

| A30700 (grade) | 2 | 700 | 1189 | 6.69 (170) | 2.08 (53) | 27.87 (708) | 3.94 (100) | 12.1 | 5.5 | E30850 (grade) |

| A30850 (grade) | 2 1/2 | 850 | 1444 | 8.66 (220) | 2.75 (70) | 28.97 (736) | 3.94 (100) | 23.1 | 10.5 | E31140 (grade) |

| A30900 (grade) | 3 | 900 | 1529 | 8.86 (220) | 2.75 (70) | 28.97 (736) | 3.94 (100) | 23.1 | 10.5 | E31140 (grade) |

| A30900 (grade) | 3 | 900 | 1529 | 8.66 (220) | 2.75 (70) | 28.97 (736) | 3.94 (100) | 23.1 | 10.5 | E31140 (grade) |

| A31250 (grade) | 3 | 1250 | 2125 | 8.86 (220) | 2.75 (70) | 33.74 (857) | 3.94 (100) | 25.4 | 11.5 | E31160 (grade) |

| A31500 (grade) | 3 | 1500 | 2550 | 8.66 (220) | 2.75 (70) | 39.56 (1005) | 3.94 (100) | 27.6 | 12.5 | E31175 (grade) |

*Rated flow at 100 psig (7 barg), reference conditions at 14.7 psi(a) (1.014 bar (a)) 68 °F (20 °C)

| Grade | X5 | X1 | XA | AC | ||||

| Partial removal | 5 micron | 1 micron | 0.01 micron | 0.01 micron | ||||

| Max particle size class** | 4 | 3 | 1 | 1 | ||||

| Max oil content** | 4 | 3 | 1 | 1 | ||||

| Max oil carryover at 68 °F (20 °C) | 5ppm | 5 mg/m3 | 0.3 ppm | 0.3 mg/m3 | 0.01ppm | 0.01 mg/m3 | 0.003 ppm | 0.003 mg/3 |

| Pressure loss – clean & dry | 0.6 psi | 40 mbar | 0.8 psi | 55 mbar | 1.2 psi | 85 mbar | 1.7 psi | 115 mbar |

| Pressure loss – saturated | 1.1 psi | 75 mbar | 1.8 psi | 125 mbar | 1.8 psi | 125 mbar | N/A | |

| Pressure loss – element change | 12 months | 8000 hours | 8000 hours | 12 months | 8000 hours | 12 months | at least every 6 months | |

| Max temperature – automatic drain | 176 °F | 80 °C | 176 °F | 80 °C | 176 °F | 80°C | 122 °F*** | 50 °C*** |

| Max working pressure – automatic drain | 232 psig | 16 barg | 232 psi | 16 barg | 232 psig | 16 barg | 232 psig | 16 barg |

| Max temperature – manual drain | 248 °F | 120 °C | 248 °F | 120°C | 248 °F | 120 °C | 122 °F*** | 50 °C*** |

| Max working pressure – manual drain | 300 psig | 20.7 barg | 300 psig | 20.7 barg | 300 psig | 20.7 barg | 300 psig | 20.7 barg |

| Element end cap color | Green | Red | Blue | Black | ||||

** to ISO 8573-1: 2010 *** Maximum recommended operating temperature 77 °F (25 °C)

| Pressure Correction Factors | For maximum flow rate, multiply model flow rate by the correction factor corresponding to the minimum operating pressure | Operating pressure psig (barg) | 58(4) | 72 (5) | 87 (60) | 100 (7) | 115 (8) | 145 (10) | 174 (12) | 203 (14) | 232 (16) | 300 (20.7) |

| 100 psig – correction factor | .076 | 0.84 | 0.92 | 1.00 | 1.07 | 1.19 | 1.31 | 1.41 | 1.51 | 1.73 |

Technical Notes

- Direction of air flow is inside to out through the filter element.

- Pop up indicators (65DPUG3) are fitted to models A30025 to A30050 as standard. Differential pressure indicators (65DPIG) are fitted to models A30070 to A31500 as standard. Activated Carbon (AC) grade filters do not include DP equipment. Volt free contact options are available upon request – see price guide.

- Coalescing Filters are fitted as standard with normally open float operated automatic drain valves, ADVS16 on models A30006 to A30050 and ADVSE16 on models A30070 to A31500, and manual drain valves on Activated Carbon Filters. Standard filters can operate at 232 psig (16 barg) at 176 °F (80 °C). Normally closed float operated automatic drain valves (ADVS16C) are available for low range flow applications (2.5 SCFM, 4.2 Nm3/hr or lower). 300 psig (20.7 barg) range at 248 °F (120 °C) available when supplied with a manual drain valve (MDV25 on models A30006 to A30050 and MDVE25 on models A30070 to A31500).

- Activated Carbon Filters must not operate in oil saturated conditions and will not remove certain types of gases including carbon monoxide (CO) and carbon dioxide (CO2).

- Alpha Filters are manufactured from cast aluminum alloy and are PED 2014/68/EU compliant for group 2 gases.

- Standard threaded connections are NPT to ANSI/ASME B1.20.1. RP (BSP Parallel) to ISO 7-1 and RC (BSP Taper) to ISO 7-1 are also available upon request.

- Filters are suitable for use with mineral and synthetic oils plus, oil-free compressed air applications.

Please contact us directly and we will help you find your product.